Features and Specifications:

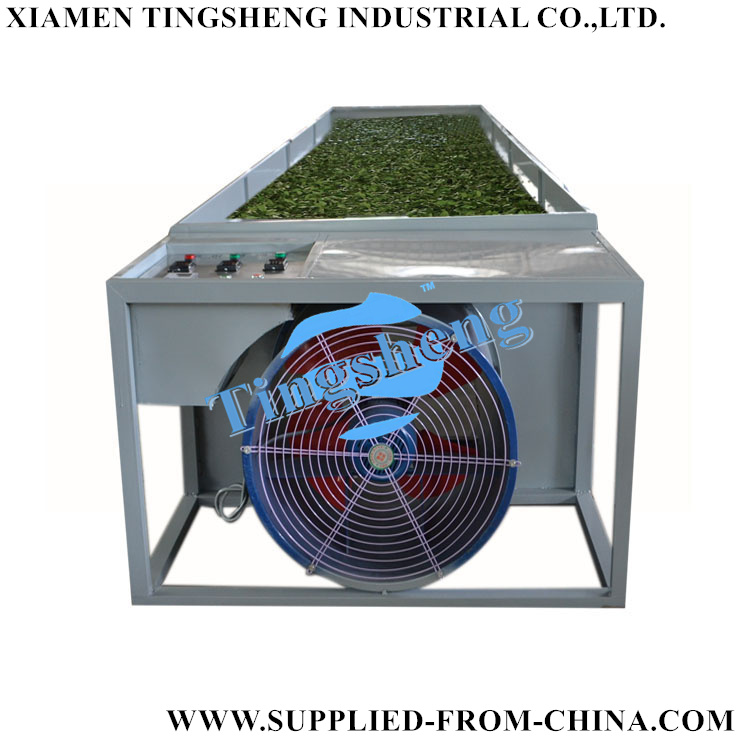

The picked fresh leaves are spread out at a certain thickness and made to appear wilted by drying. During the withering process, a series of changes occur in the fresh leaves: the water is reduced, the leaves become soft from brittle and hard, which is easy to be twisted into strips; the activity of the enzymes contained in the leaves is enhanced, prompting the decomposition and transformation of fresh leaf components such as starch, protein and insoluble protopectin to produce glucose, amino acids, bathable pectin and other effective substances that are beneficial to the quality of tea, and the polyphenols are also oxidized to varying degrees. The normal and effective withering makes the fresh leaves' grassiness subside and produce clear fragrance, and fruit fragrance or floral fragrance, and the finished tea tastes mellow but not bitter and astringent. Withering requires suitable temperature, humidity and air circulation. The first process in the production of white tea, black tea and green tea is withering, but the degree varies. White tea withering is the heaviest, and the water content of fresh leaves is required to drop below 40%; black tea withering is the second heaviest, and the water content is reduced to about 60%; green tea withering is the lightest, and the water content is required to be between 68-70%.

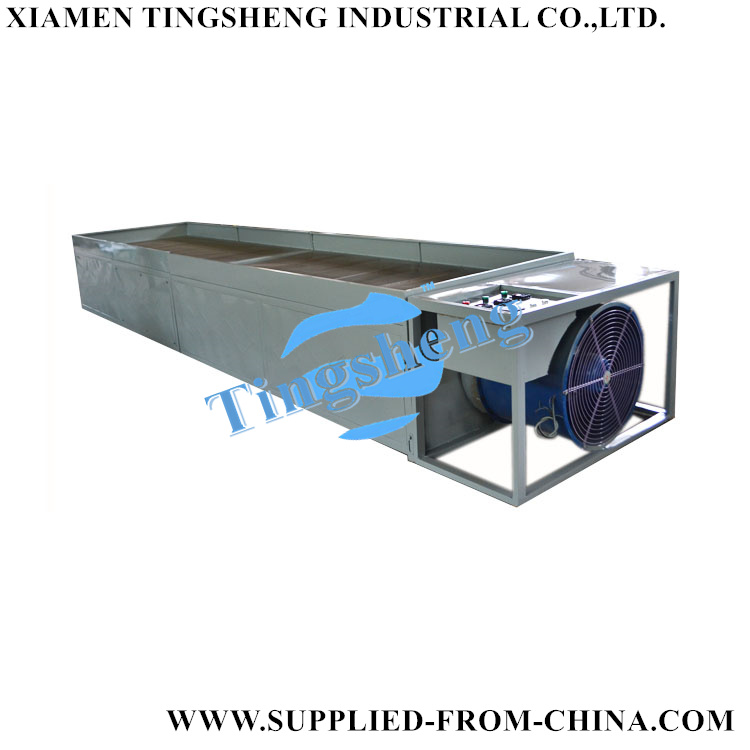

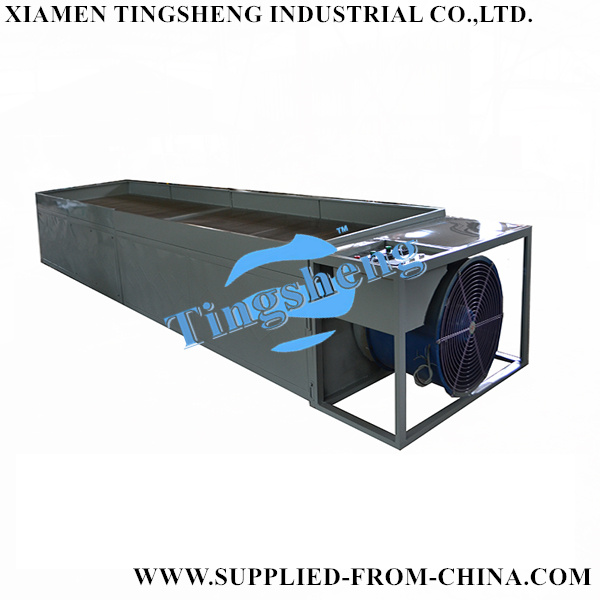

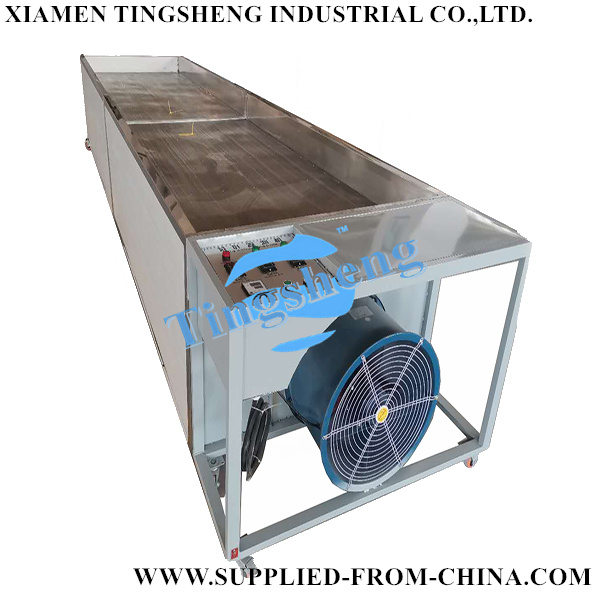

| Model | TS-TWM-10B |

| Outside dimensions | 1100mm Width x 770mm Height x 10500mm Length(Bespoke service available ) |

Work output (tedding calculated on basis of fresh leaves) | 20-25kg/m |

Work voltage & power | Three-phase 380V50Hz ,13kw |

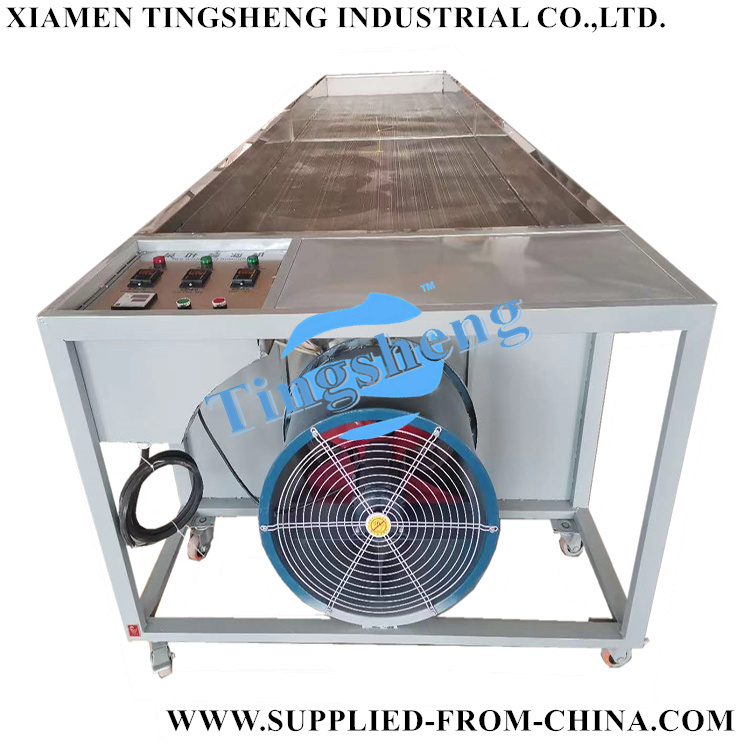

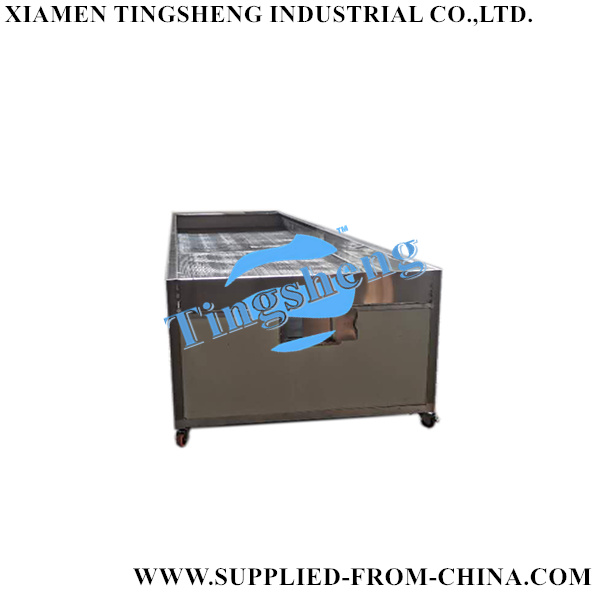

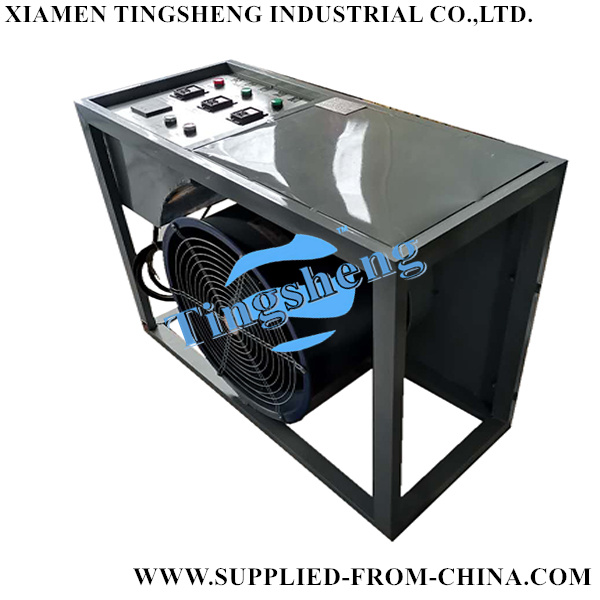

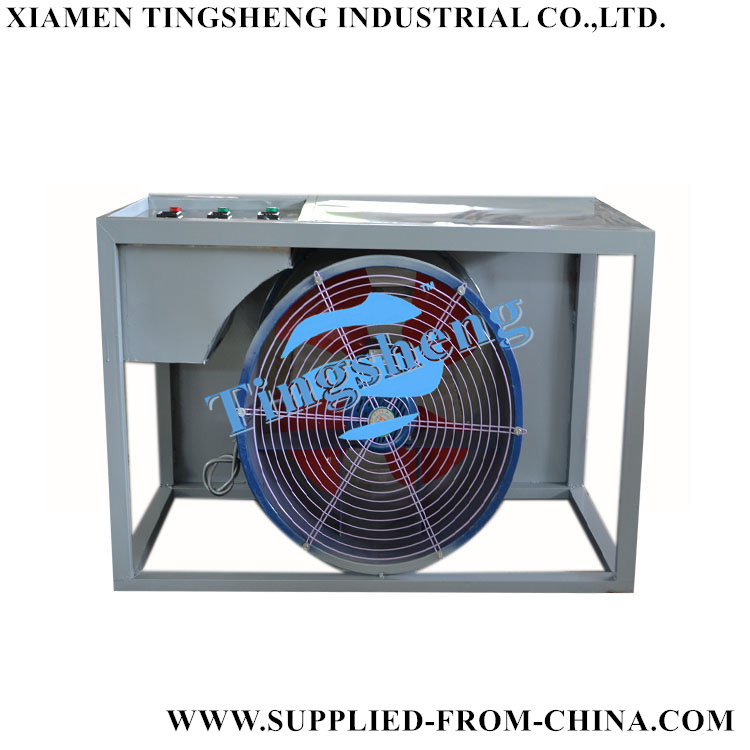

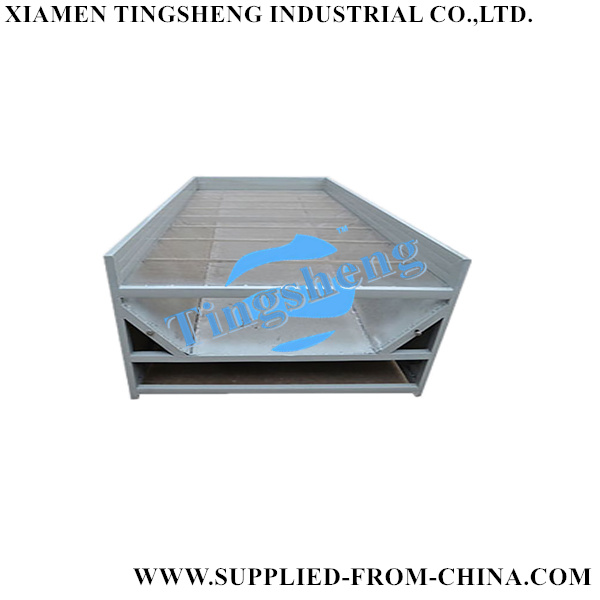

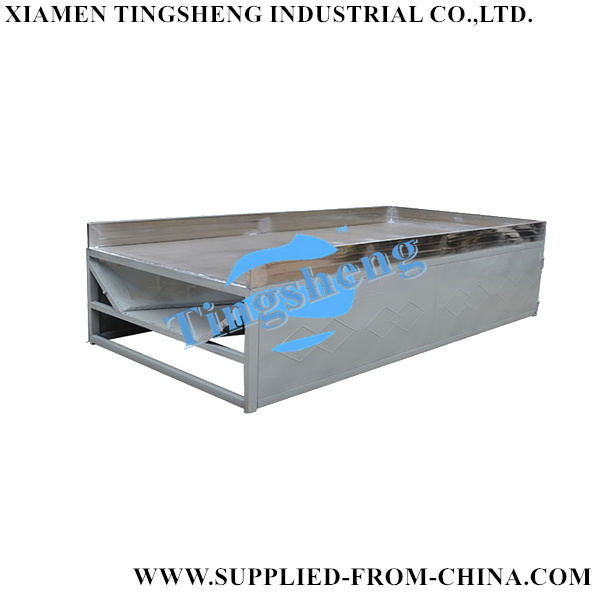

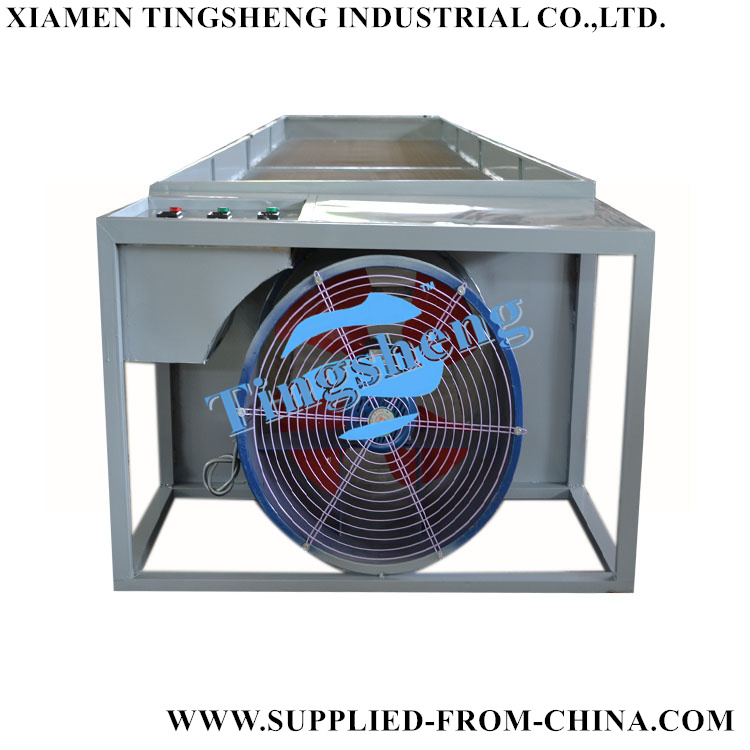

Pictures: